Did you know that most of the small plastics used in marijuana packaging can’t actually be recycled by the city? That’s right. Even though your cannabis product might come in a recyclable material, that doesn’t mean your city has the right equipment to process the packaging. For example, in Phoenix Arizona the city has a recycling program, but the equipment simply cannot recycle plastic or glass objects smaller than two inches in diameter.

This means all of your little flower jars, preroll tubes and edible containers are literally falling through the cracks and ending up in a landfill somewhere… and this is a growing issue!

When cannabis finally started becoming legal in the US, it didn’t take long for new, individually wrapped products to arrive in the marketplace. Unfortunately, due to child resistant packaging laws and really a lack of packaging innovation, plastic waste has dramatically increased from the cannabis industry over the last few years.

It would be easy to blame the manufactures of all of this packaging, but the truth is there still need to be a number of legislative changes at the industrial level that need to be made before brands can even legally invest into new solutions.

So, in the meantime, what can be done?

Luckily there are some good people who are trying to help. Today we are talking to one of those good people: Garret Schwartz, Co-founder of Resinate.

Resinate is an upcycling company full of people so talented and dedicated that it actually works – they collect plastic waste from local businesses (often ones that don’t have access to a recycling program) and reprocess that waste into 100% recycled plastic products. This saves recyclable materials from the fate of landfills or incinerators and instead produces durable, eventually recyclable products. How cool is that?

Here is a copy of our interview:

Jenny: Garret, we see so many cannabis dispensaries carry products in extremely fancy packaging and wondered how much of it is actually recyclable. We were shocked to learn how much is actually not getting recycled. Is this initially what sparked your idea to start Resinate?

Garret: Yes and no. I was interested in solving a problem in recycling, and as a patient who uses medical cannabis to treat multiple spine conditions, I knew first-hand what a dresser drawer full of empty cannabis containers looked like.I had multiple reasons for not wanting to put them into the regular blue recycling bin, so when I learned about recycling problems specific to these items, I couldn’t look away and became obsessed with understanding and helping to solve the problem.

Around January 2018, I was talking with a friend about the concept of recycling locally, when one of us mentioned the notion that only 7% of plastic waste produced in the US gets recycled, and we realized that it was this larger problem which we wanted to understand and help solve. That was around the same time China’s National Sword Policy began to take effect, which reduced China’s recycling imports to 0 as of January 2021. This and other global halts to traditional recycling imports caused recyclers around the world to scramble, cut costs, discontinue recycling certain materials, and evaluate the future. My friend and I saw this, and we simply asked “what’s recyclable but not getting recycled?” to find out that small plastics literally fall through the cracks of existing recycling systems.

Recyclability and recycling rates are practically 0% when it comes to cannabis packaging in most places in the US, but these issues exist in many industries (some of which are actively working to improve and innovate with new partnerships and systems). Part of the reason for this low number is access to recycling, and part of it is the global recycling infrastructure. While researching, we visited Phoenix recycling centers and landfills to learn that even though small plastic containers are composed of recyclable materials, the containers themselves literally fall through the cracks of recycling sorting systems before they reach human or robotic sortation.

I toured the materials recovery facility at the Phoenix North Gateway Transfer Station with Phoenix’s Zero Waste Coordinator Lucas Mariacher, I stood at the part of the facility where the loose, unsorted items entered the system on a conveyor belt, and I watched a joint tube be pushed up the conveyor belt with other items into an assembly of tumbling disks where larger items like water bottles and yogurt tubs were pushed up across the disks to the next section, and the joint tube fell down between the disks. This is how small plastics fall through the cracks of traditional recycling systems and go to landfills. I also learned from the operators that even though this recycling center would undergo a $4.5 million upgrade, the “falling through the cracks” problem would still remain. People needed a system that works for these materials, and they needed better access.

I knew there was potential to change the present and the future with a new diversion model rooted in capturing these small items in a strategic and thoughtful way. Beyond that, we didn’t just want to divert plastic from landfill; we wanted to do something more with it than traditional models which have contributed to waste, global dysfunction, and pollution.

Jenny: Do cannabis dispensaries typically have access to recycling programs?

Garret: Not really. Even if dispensaries pay the costs of a traditional recycling service, these services do not capture and recycle cannabis packaging. Much like when you try to recycle cannabis packaging in the blue bin at home, a traditional recycler will end up sending these items to landfill as they fall through the cracks, and people are left in the dark about what happens with their recyclables. Cannabis dispensaries in some states do have access to specialized recycling programs, but each of these programs only captures one type of material and then typically brings it to a processor/exporter of low-quality, aggregated granulate (rather than transparently and locally capturing more value and diverting into long-term products).

Jenny: How does the Resinate Recycling program work?

Garret: At participating dispensaries with the Energy Pod (our futuristic recycling bin) people can bring any type of plastic cannabis packaging to recycle. The Energy Pod provides an easy and compliant process for the dispensary operator, while making the experience safe, interactive, and fun for the recyclers. The packaging should be empty, dry, and free of contaminants, but we do not require labels to be removed. Recyclers can use a QR code located directly above the Energy Pod to perform photo-validation of recycling participation so they can receive emailed rewards coupons, learn about the impact of their work, and make new connections with our locations and recycling sponsors. We use customized hardware to prevent contamination and increase interaction, and we use IOT tech and logistical partnerships to optimize collection and maximize process efficiency.

Jenny: What products do you make from your recycled plastics?

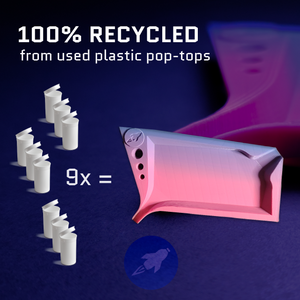

Garret: During the last few years, we’ve improved a process for fully recycling and manufacturing using 100% recycled plastic that we collect. A couple years of experience have taught us how to mix and melt plastics in a lovely way, resulting in the swirled marbling you see in most of our end products. This involves a proprietary de-labeling process, a motorized shredding system and a hydraulic mold injection press. Right now, we make one product: the Little Stash Jar, which is mostly only available at our participating recycling locations and the website of one of our sponsors. Each little stash jar is made from 6 pop-tops that would have gone into landfills or ecosystems. We have one product design released, the patent-pending, bowl-fulling, cone-stuffing Twisted Tray, which we plan to begin production on this summer.

Jenny: Do you recycle other small, non-cannabis related product packaging?

Garret: Yes we do! Any small, non-hazardous pharmaceutical or OTC packaging can be recycled in the Energy Pod, although we are looking at alternative models for these items in the long term. Over 4 billion prescriptions are filled in the US each year, and we know that’s a lot of waste.

Jenny: Do you only recycle plastic?

Garret: Yes – since plastic waste is still growing and is the most common and most potentially hazardous of these materials, we’re focused on making a significant impact on its carbon footprint first. We understand a similar need to capture other items, especially glass containers in the cannabis industry. These are composed of recyclable materials but similarly not recyclable due to their small size. We plan to expand our service to incorporate glass recycling but we are not releasing a date yet.

Jenny: Is this program only available in Arizona?

Garret: Yes, Resinate’s program is only available in Arizona, and it is (to our knowledge) the only service in the United States that allows participants to recycle all types of plastic canna-packaging. It is also the only service that allows participants to get ongoing rewards for recycling, to see how the recycling process works, and to engage with the end product of their recycling. That’s closing the loop!

Jenny: How else can we get involved if we want to help?

Garret: If you’re looking for basic ways to improve the way you change the world, one step is to consider how to “recycle right” with traditional recycling if you have it. Avoid putting plastics in the recycling bin if they’re smaller than 2.5 inches in diameter (the width of a typical water bottle), and definitely don’t put soft, flexible plastics in the recycling bin. Mixed recyclables are sorted using both automated and human-powered processes, so when we reduce the clutter of items that can’t be recycled in these systems, their processes can capture more items that can be captured, which means these systems are more efficient, and this allows more opportunity and less expense for the recycler and the consumer.

Another thing you can do: look for, ask for, and support better systems. Hemp-based and plant-based plastics can reduce the carbon footprint of packaging, so let your dispensary know you’d like to see them try more sustainable alternatives like these, but that these items still need to be captured by a program like Resinate. If you have a question about recyclability, reuse, alternative materials, or anything we could help with, we encourage you to send an email to hello@resinate.tech or DM us at instagram.com/WeCanResinate.

If you’re interested in empowering Resinate to do more, let’s talk. Learn more about our services and products or message us directly with the links above. We also have some custom acid-washed Resinate shirts we’re coming out with next month to help #fuelthemission and we can’t wait to get the patent-pending, cone-stuffing, bowl filling Twisted Tray into production!

Jenny: What else do you want us to know?

Garret: The future of cannabis packaging, recycling, and sustainability will be in the hands of brands and operators more than ever, and that’s a good thing if they make good choices. Wholesalers and retailers have a burning desire to be part of the solution, but they also have an interest in minimizing expenses and protecting their bottom line. We can’t just tell them to choose more sustainable options, we have to create and show them thoughtful solutions that can benefit their business.

Resinate (and recycling in general) is not a silver bullet for the issue of sustainable cannabis packaging. We expect to see changes and challenges continue in the market, and we must work together to ensure a better future. Compostable hemp-based packaging, for example, can be a significant improvement from petroleum-based plastics, but only if we can ensure that the majority of it goes to an appropriate composting process rather than into landfills.

The Boon Room is more than a website, brand or service. It’s an idea. It’s a project. It’s a mission. It’s a coming together of companies, investors, cultivators, manufacturers, distributors, retailers and inspired entrepreneurs who believe businesses need to look for ways to invest in sustainablity.